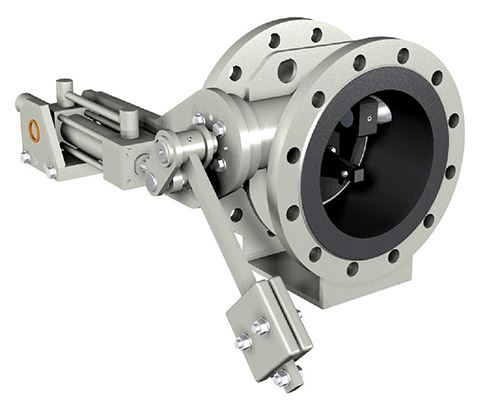

Tilting Check Valve

Tilting check valve V2-09G with double eccentric mounted disc, hard rubber inside

The AZS tilt check valve type V2-09G is a free moving check valve with lever and closing weight. The valve disc is mounted double eccentrically, opening and closing is effected by flow forces. For special operating cases, the check valve can be supplied with an additional hydraulic damping unit.

Features:

- compatible with S+S swing check valve type C1

- robust design

- streamlined design of the body and the disc

- tight closure in closed position

Versions:

- with lever and closing weight:

Normal design for all dampers that open under the action of the flow forces (direction) and close without additional damping. - with lever, closing weight and damper:

Normal design for all dampers that open under the action of the flow forces(direction) and close with damping in the last third of the closing stroke. The effect of the damping device can be adjusted on site by setting the throttle in the damper: the closing time can be changed by several seconds in this range. Dampers for setting much longer closing times are available on request (special design).

Application

- application: for liquids: water, seawater, oil, cooling water, alkalis and acids.

Materials

- housing GGG40, hard rubber inside

- valve disc GGG40, hard rubberized

- corrosion protection outside: powder coating EKB 250mg

Attention

- the outside lever moves 90°. In this range of movement it is recommended to install a protective grille

- the use of this check valve should be secured with a pressure surge calculation

Technical Data

Tilt check valve with external lever and closing weight, hard rubber inside

PN10 / PN16 / PN25 / PN40

PN10

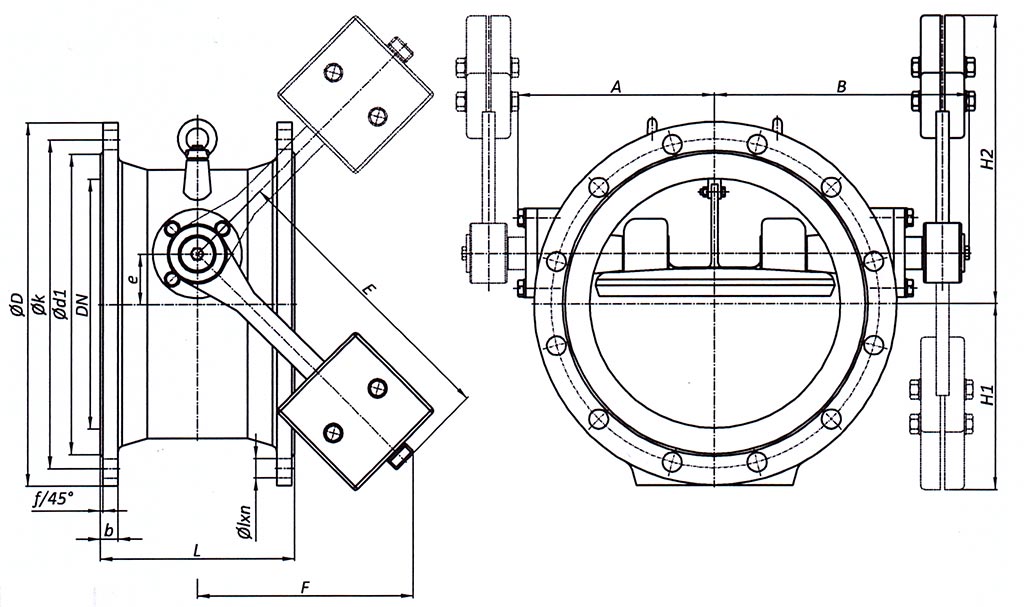

| DN | L | D | k | d1 | n | l | b | f | e | A | B | F | E | H1 | H2 | m (kg) |

| 200 | 230 | 340 | 295 | 266 | 8 | 23 | 20 | 3 | 40 | 204,5 | 254,5 | 213 | 300 | 213 | 293 | 54 |

| 250 | 250 | 395 | 350 | 319 | 12 | 23 | 22 | 3 | 48 | 237 | 306 | 213 | 300 | 205 | 301 | 70 |

| 300 | 270 | 445 | 400 | 370 | 12 | 23 | 24,5 | 4 | 62 | 260 | 400 | 319 | 450 | 305 | 429 | 95 |

| 350 | 290 | 505 | 460 | 429 | 16 | 23 | 24,5 | 4 | 70 | 276 | 359 | 319 | 450 | 298 | 438 | 140 |

| 400 | 310 | 565 | 515 | 480 | 16 | 28 | 24,5 | 4 | 81 | 315 | 446,5 | 425 | 600 | 407 | 569 | 190 |

| 450 | 330 | 615 | 565 | 530 | 20 | 28 | 25,5 | 4 | 90 | 360 | 454,5 | 425 | 600 | 398 | 578 | 210 |

| 500 | 350 | 670 | 620 | 582 | 20 | 28 | 26,5 | 4 | 100 | 365 | 464 | 425 | 600 | 388 | 588 | 240 |

| 600 | 390 | 780 | 725 | 682 | 20 | 31 | 30 | 5 | 124 | 500 | 622 | 460 | 650 | 421 | 669 | 360 |

| 700 | 430 | 895 | 840 | 794 | 24 | 31 | 32,5 | 5 | 145 | 480 | 610 | 531 | 750 | 471 | 761 | 520 |

| 800 | 470 | 1015 | 950 | 901 | 24 | 34 | 35 | 5 | 165 | 550 | 670 | 601 | 850 | 521 | 851 | 650 |

| 900 | 510 | 1115 | 1050 | 1001 | 28 | 34 | 37,5 | 5 | 160 | 606 | 855 | 691 | 980 | 636 | 956 | 910 |

| 1000 | 550 | 1230 | 1160 | 1112 | 28 | 37 | 40 | 5 | 203 | 642,5 | 810 | 601 | 850 | 499 | 905 | 1200 |

| 1200 | 630 | 1455 | 1380 | 1218 | 32 | 41 | 45 | 5 | 300 | 800 | 940 | 750 | 1100 | 609 | 1209 | 2000 |

* other nominal sizes on request

PN16

| DN | L | D | k | d1 | n | l | b | f | e | A | B | F | E | H1 | H2 | m (kg) |

| 200 | 230 | 340 | 295 | 266 | 12 | 23 | 20 | 3 | 40 | 204,5 | 254,5 | 213 | 300 | 213 | 293 | 54 |

| 250 | 250 | 405 | 355 | 319 | 12 | 28 | 22 | 3 | 48 | 237 | 306 | 213 | 300 | 205 | 301 | 70 |

| 300 | 270 | 460 | 410 | 370 | 12 | 28 | 24,5 | 4 | 62 | 260 | 400 | 319 | 450 | 305 | 429 | 95 |

| 350 | 290 | 520 | 470 | 429 | 16 | 28 | 26,5 | 4 | 70 | 276 | 359 | 319 | 450 | 298 | 438 | 140 |

| 400 | 310 | 580 | 525 | 480 | 16 | 31 | 28 | 4 | 81 | 315 | 446,5 | 425 | 600 | 407 | 569 | 190 |

| 450 | 330 | 640 | 585 | 548 | 20 | 31 | 30 | 4 | 90 | 360 | 454,5 | 425 | 600 | 398 | 578 | 210 |

| 500 | 350 | 715 | 650 | 609 | 20 | 34 | 31,5 | 4 | 100 | 365 | 464 | 425 | 600 | 388 | 588 | 240 |

| 600 | 390 | 840 | 770 | 720 | 20 | 37 | 36 | 5 | 124 | 500 | 622 | 460 | 650 | 421 | 669 | 360 |

| 700 | 430 | 910 | 840 | 794 | 24 | 37 | 39,5 | 5 | 145 | 480 | 610 | 531 | 750 | 471 | 761 | 520 |

| 800 | 470 | 1025 | 950 | 901 | 24 | 41 | 43 | 5 | 165 | 550 | 670 | 601 | 850 | 521 | 851 | 650 |

| 900 | 510 | 1125 | 1050 | 1001 | 28 | 41 | 46,5 | 5 | 160 | 606 | 855 | 691 | 980 | 636 | 956 | 910 |

| 1000 | 550 | 1255 | 1170 | 1112 | 28 | 44 | 50 | 5 | 203 | 642,5 | 810 | 601 | 850 | 499 | 905 | 1200 |

| 1200 | 630 | 1485 | 1390 | 1218 | 32 | 50 | 57 | 5 | 300 | 800 | 940 | 750 | 1100 | 609 | 1209 | 2350 |

* other nominal sizes on request

PN25

| DN | L | D | k | d1 | n | l | b | f | e | A | B | F | E | H1 | H2 | m (kg) |

| 200 | 230 | 360 | 310 | 274 | 12 | 28 | 22 | 3 | 40 | 204,5 | 254,5 | 213 | 300 | 213 | 293 | 60 |

| 250 | 250 | 425 | 370 | 330 | 12 | 31 | 24,5 | 3 | 48 | 237 | 306 | 213 | 300 | 205 | 301 | 77 |

| 300 | 270 | 485 | 430 | 389 | 16 | 31 | 27,5 | 4 | 62 | 260 | 400 | 319 | 450 | 305 | 429 | 105 |

| 350 | 290 | 555 | 490 | 448 | 16 | 34 | 30 | 4 | 70 | 276 | 359 | 319 | 450 | 398 | 438 | 153 |

| 400 | 310 | 620 | 550 | 503 | 16 | 38 | 32 | 4 | 81 | 315 | 446,5 | 425 | 600 | 407 | 569 | 200 |

| 500 | 350 | 730 | 660 | 609 | 20 | 38 | 36,5 | 4 | 100 | 365 | 464 | 425 | 600 | 388 | 588 | 264 |

| 600 | 390 | 845 | 770 | 720 | 20 | 41 | 42 | 5 | 124 | 500 | 622 | 460 | 600 | 421 | 669 | 396 |

| 700 | 430 | 960 | 875 | 820 | 24 | 44 | 46,5 | 5 | 145 | 480 | 610 | 531 | 750 | 471 | 761 | 572 |

| 800 | 470 | 1085 | 990 | 928 | 24 | 50 | 51 | 5 | 165 | 550 | 670 | 601 | 850 | 521 | 851 | 715 |

* other nominal sizes on request

PN40

| DN | L | D | k | d1 | n | l | b | f | e | A | B | F | E | H1 | H2 | m (kg) |

| 200 | 230 | 375 | 320 | 284 | 12 | 31 | 30 | 3 | 40 | 204,5 | 254,5 | 213 | 300 | 213 | 293 | 64 |

| 250 | 250 | 450 | 385 | 345 | 12 | 34 | 34,5 | 3 | 48 | 237 | 306 | 213 | 300 | 205 | 301 | 85 |

| 300 | 270 | 515 | 450 | 409 | 16 | 34 | 39,5 | 4 | 62 | 260 | 400 | 319 | 450 | 305 | 429 | 110 |

| 350 | 290 | 580 | 510 | 465 | 16 | 38 | 44 | 4 | 70 | 276 | 359 | 319 | 450 | 298 | 438 | 158 |

| 400 | 310 | 660 | 585 | 535 | 16 | 41 | 48 | 4 | 81 | 315 | 446,5 | 425 | 600 | 407 | 569 | 210 |

* other nominal sizes on request

Technical changes reserved —Tolerance standard dimensions according to DIN / ANSI, other dimensions are guide values